Sniffer4D For Pipeline Inspection

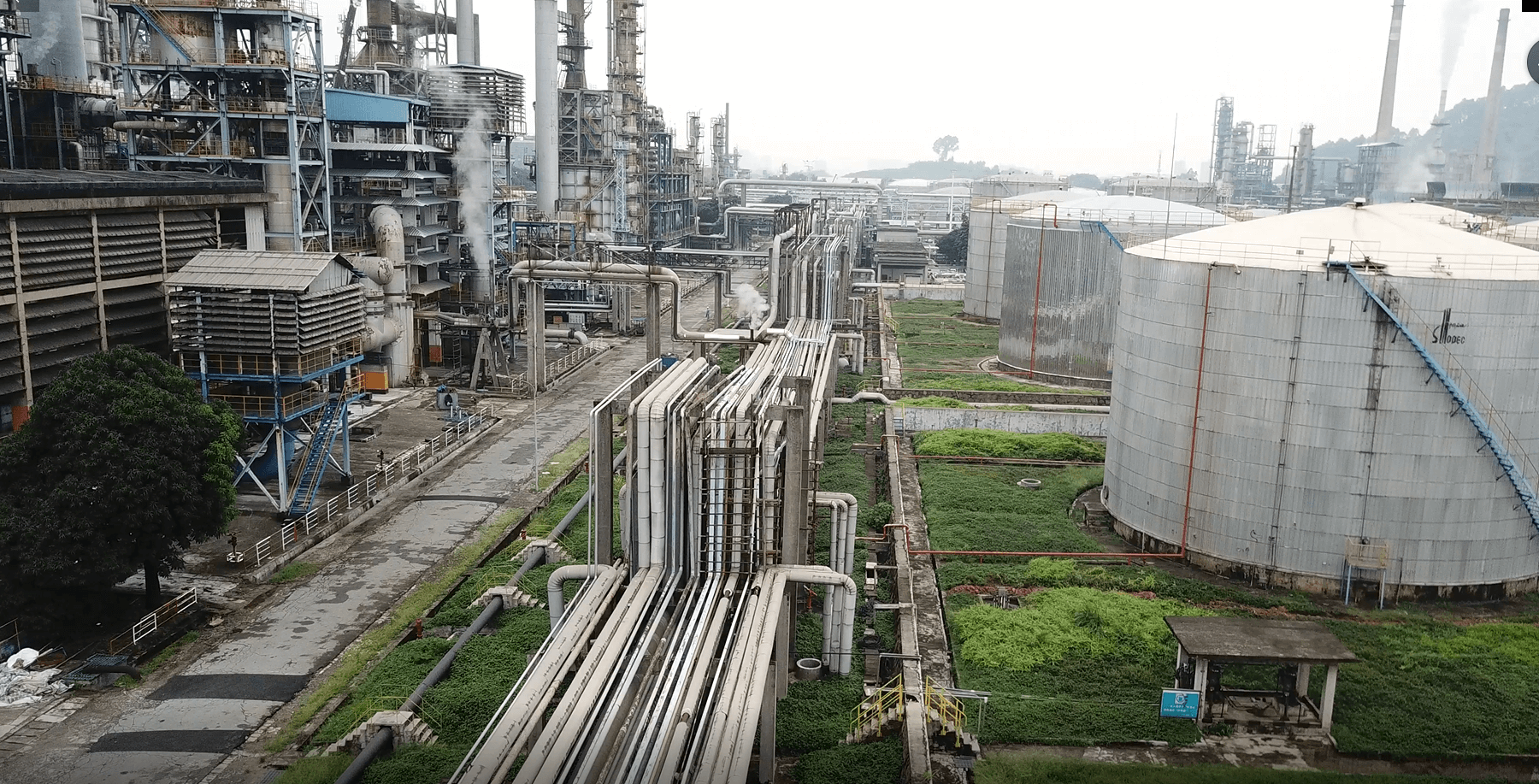

For petrochemical enterprises, it is an important part of their safety work to have regular inspections upon oil and gas pipelines to prevent leaking. However, due to the wide and complex distributions of the pipelines, there are many limits to the traditional manual inspection methods. The disadvantages include heavy workload, high labor cost, low efficiency, safety risk of the personnel, time limit on the inspection and difficulties in quality control.

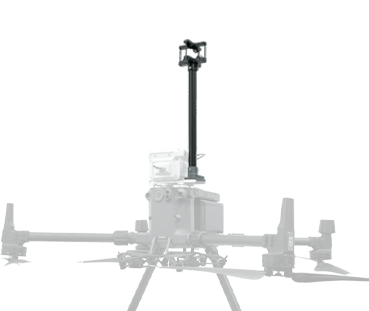

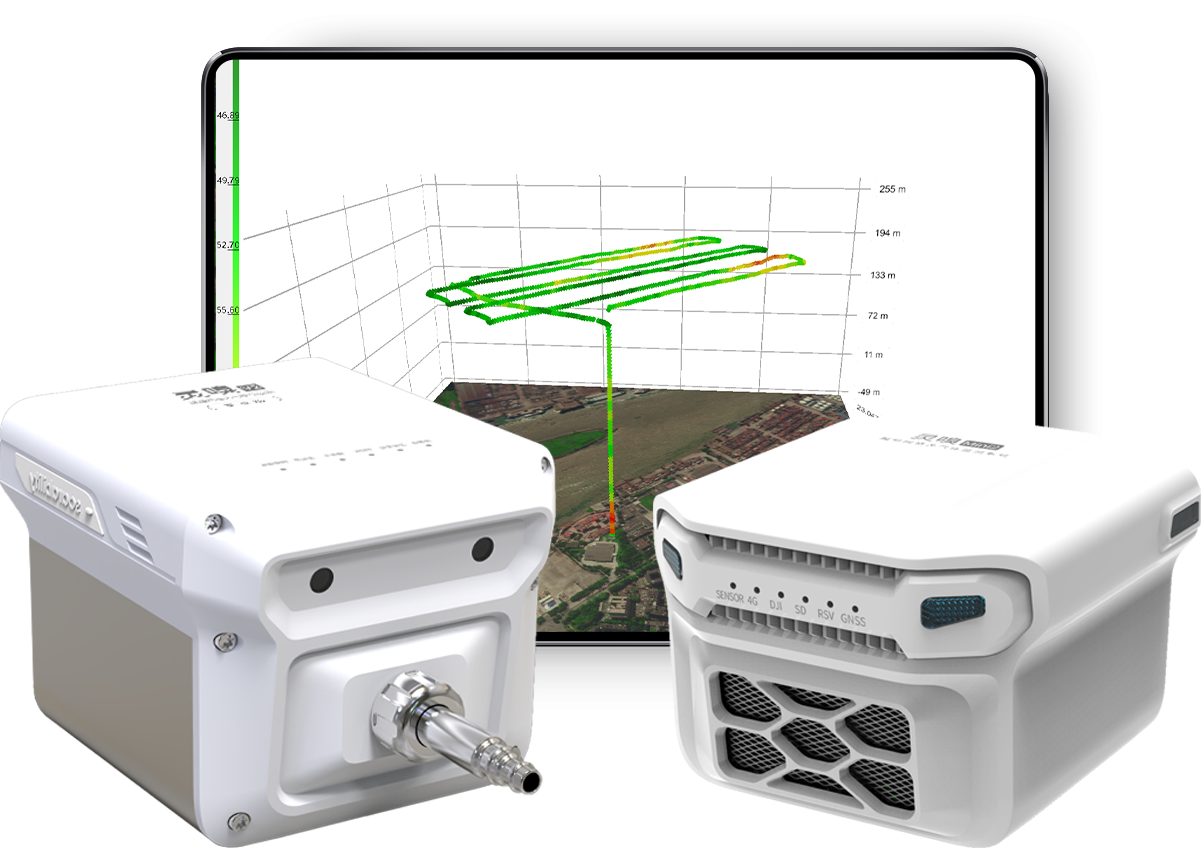

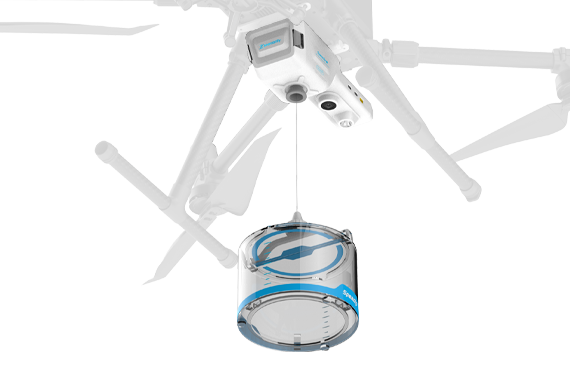

Aiming at the pain points of manual inspections, the gas detection based on the integration of Sniffer4D multi-gas detection system (XP2 rated) and drone can assist the oil and gas pipeline inspections to a large extent.

Recently, Soarability delivered a set of drone-mounted Sniffer4D gas detection system to one of the quality supervision institutions in Guangzhou. And the system was designed for inspection of the oil and gas pipelines.

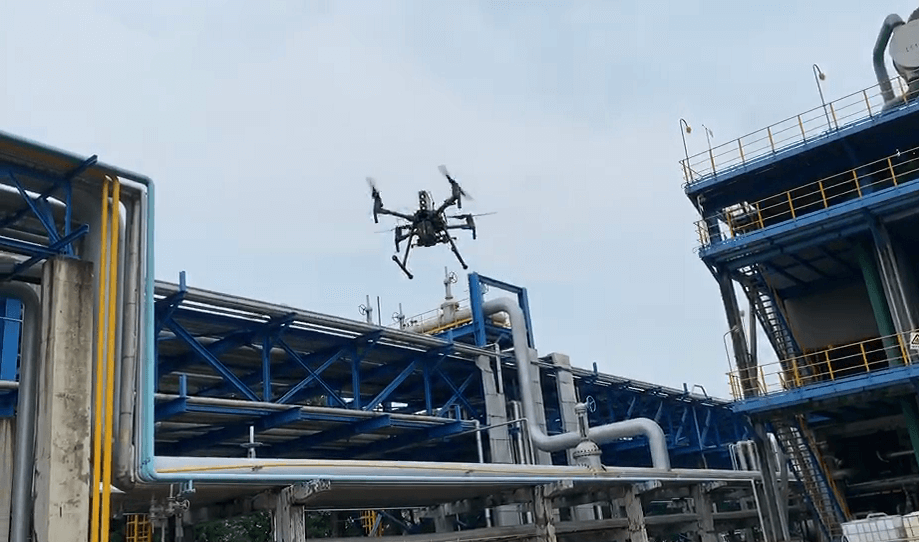

At the scene, the inspection crew operated the drone to lift off with Sniffer4D and to scan the area within 3 meters above the oil and gas pipelines. Meanwhile, they paid close attention to the methane and VOCs concentrations and the gradient changes displayed in the Sniffer4D Mapper software.

The drone carried Sniffer4D and scanned the area within 3m above the pipelines.

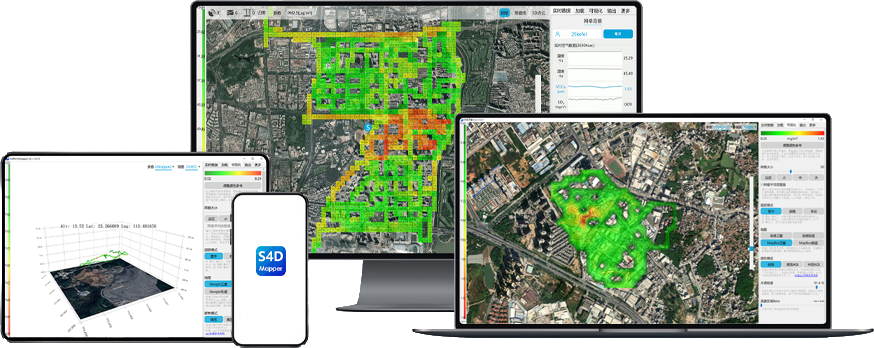

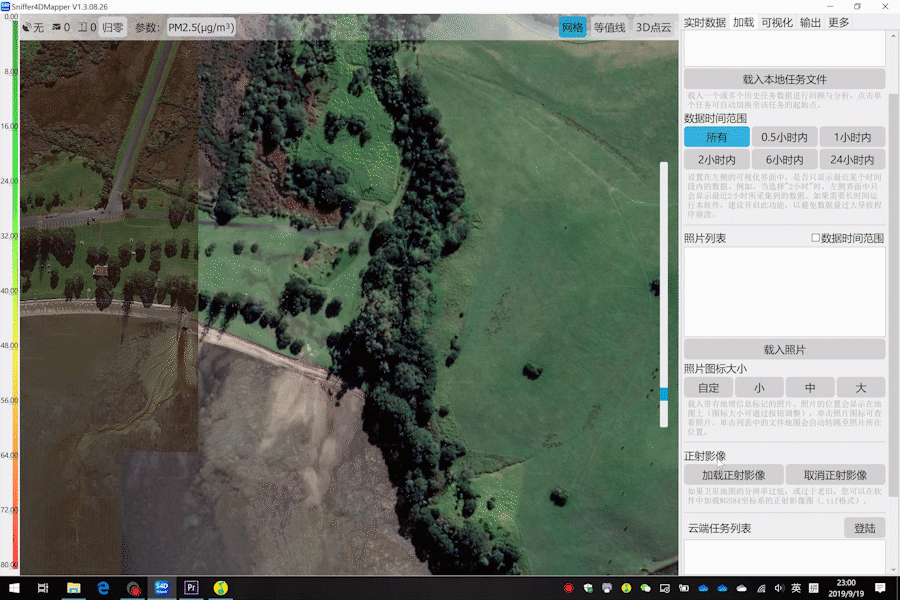

At the same time, the analytical software Sniffer4D Mapper displayed the dynamic changing process of the gas concentrations in real-time.

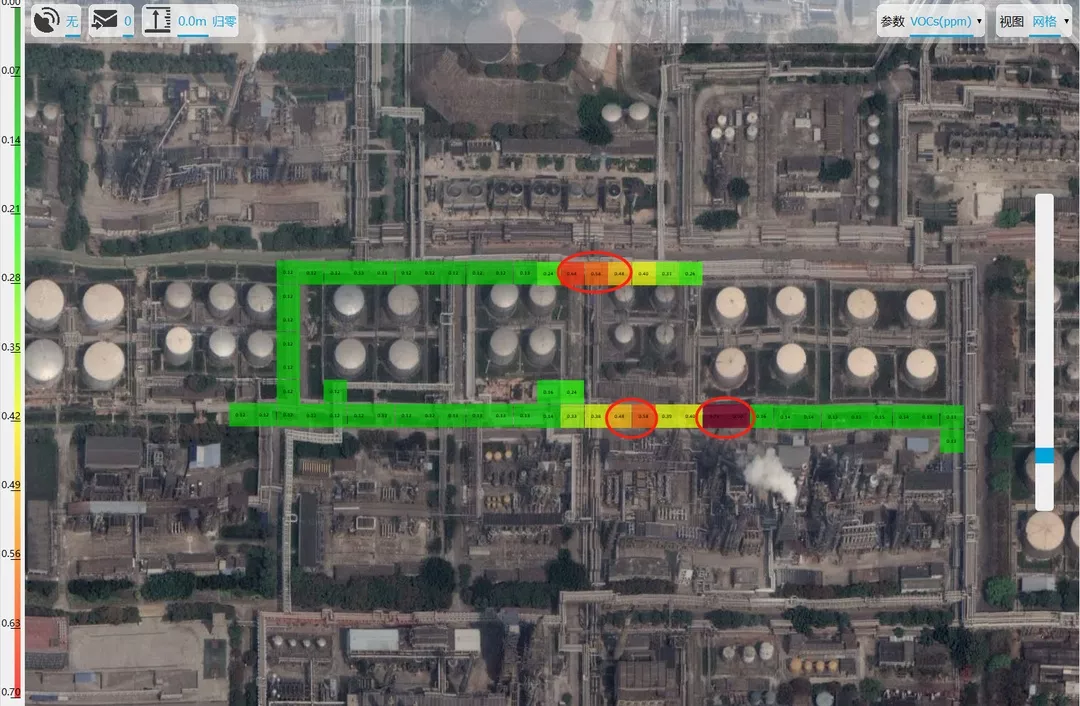

The picture below is a 2D concentration grid map generated by Sniffer4D Mapper in real-time. It shows three areas where the VOCs concentration is significantly higher than the background, which indicates that Sniffer4D quickly detects three key areas and boosts the efficiency of the inspection.

In the 2D distribution grid map of VOCs, there are three areas where the VOCs concentration is significantly higher than the background.

Due to the dense distribution of the oil and gas pipelines, the inspection crew had to combine the images and videos taken by the drone and conducted further investigation on the high-concentration areas based on the initial results.

Since the oil and gas pipelines are densely distributed in the plant, the method of using the drone to inspect and to narrow down the area before conducting manual inspection, helps to improve the efficiency and response speed of the inspection.

The key advantages of the drone-mounted Sniffer4D gas detection system

The case of pipeline inspection has shown the multiple advantages of the drone-mounted Sniffer4D gas detection system compared to the traditional manual inspection method. By combining with the manual inspection, it can dramatically boost the quality and the efficiency of the pipeline inspection:

Firstly, it can break through the limitations of terrain and other factors, choose the scanning path and direction flexibly, detect hard-to-reach places and cover the inspection area in a larger range.

The drone carried Sniffer4D and scanned from a high altitude.

Secondly, it provides short preparation time and quick speed to get started, it can also save time and labor cost, reduce the safety risk and help to discover, investigate and handle the emergencies in time.

Thirdly, the drone-mounted Sniffer4D gas detection system can directly capture images, videos and gas concentration distributions of the pipeline surroundings, then transmit the information to the inspection crew, the management crew and the technical expert far away from the scene, providing them crucial reference for decision-making.

Fourthly, Sniffer4D Mapper can generate the mission report right after the mission is accomplished. The report contains key information such as the detection time, the maximum concentration of a grid/single point, the corresponding latitude and longitude, etc., and it is attached with an intuitive concentration distributions map. All the reports can not only be used as the basic materials for reporting and further manual verification, but also be regularly sorted and compared to testify the effectiveness of hazard treatment.

After the mission is accomplished, Sniffer4D Mapper can generate the report with one click for better presentation, decision-making and data comparison.

Fifthly, Sniffer4D Mapper can import the orthophoto of the factory, if the low-resolution satellite map fails to show all the details of the industrial park, and the layers of Satellite map+HD Orthophoto+Gas distribution map can help the users accurately localize the problems.

When the satellite map is obsolete or blurry, Sniffer4D Mapper supports importing the high-resolution orthophoto, so that users can associate the gas distribution with the latest and more distinctive images of the ground objects.